This place is in the Akmola region, Kazakhstan. Here gold is mined. The history of the mine reflects the history of the country itself. It underwent declines and stagnation but finally it managed to revive.

Advertisement:

There used to be a small pit here which for 33 years turned into a huge mine 135 meters deep and as wide as 1210 thousand square meters.

Victor,55, has been working at the mine for 33 years.

He is one of those who still remember how it all began. How a small pit was slowly growing. In the middle of the 90s there was even a period when gold was not mined at all because it became very cheap (260 dollars per ounce) and the work was not financed. People had to wait for work for months. But in the middle of the 2000s the mine seemed to start its second life. They got so needed investments at last. To revive the production they needed 700 million dollars.

For the last two years they managed to mine as much gold as they had been mining for 20 years – 11,5 tons!

Now they are working nonstop.

24/7 excavators bucket the ore and load huge Caterpillars with it which transport it for crushing. Then it will go via the conveyor to the factory where gold will be extracted.

The project output should be eight million tons of ore a year. However they mine only six tons yet. Two grams of gold is found in one ton of ore. All this colossal work is done for this tiny amount of gold.

One dumptruck “CAT-777″ weighs seventy tons but its lifting capacity is 90-100 tons. It’s like a huge ant that can lift a cargo heavier than the truck itself. Besides, drivers say that CATs are even easier to drive than cars.

When CATs appeared here each was given its own name: “Jaguar”, “Vanguard”, “Golden antelope”, “Orange”, etc.

Drivers say the work has become much cleaner with such vehicles.

This is an excavator RH 120-Е TEREX. Its long-term performance is 2000 tons per hour. Only its bucket itself has a capacity of 15m ³.

The process of gold mining was absolutely different. The ore was irrigated with a solution of sodium cyanide and extracted from the rock. But that method was effective only for oxidized ore, amount of which was gradually decreasing. So they needed new technologies and big investments. Now they blast the rock and extract gold in a more sophisticated way.

First of all the deposit is measured observing the strict technological regime. Then geologists determine the presence of gold-bearing ore.

Then drillers start their work. They drill small pits sixteen meters (52 ft) deep which are going to be blasted.

The explode the rock twice a week. One hour before an axplosion all people and equipment leave and the electricity is turned off.

Then the same process starts. The excavator buckets the ore and loads it on the trucks which bring it for crushing.

The ore is crushed to the size of a fraction (350 mm (14 inches)). Then it goes to roll-presses and further to ball mills.

Crushing is carried out in two stages.

When the ore is fully crushed gold finally can be extracted.

Any visitor is strictly examined before entering.

“This person is responsible for your safety today”.

And this is a control room from where one can observe the entire production cycle.

This is a ball-mill “Outotec” specially made for the mine. There are no analogues of such size anywhere in the world.

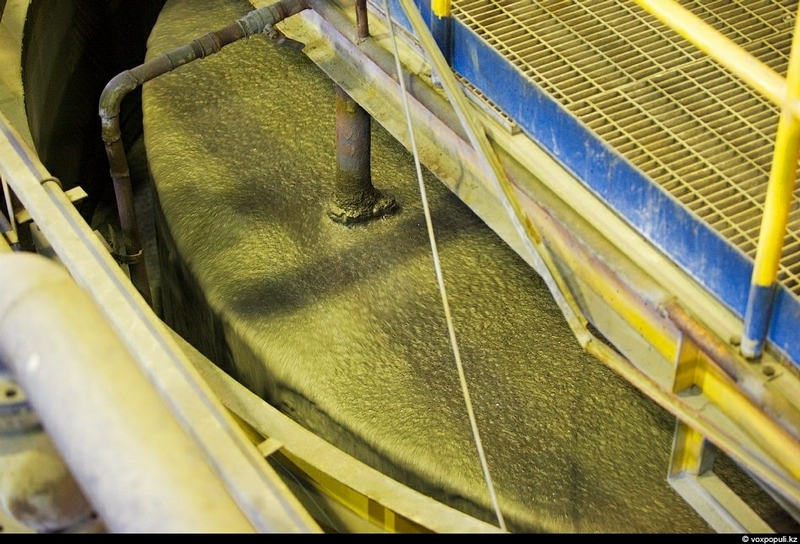

This flotation machine is intended for separation of gold from other non-ferrous metals.

It’s the flotation and gravity shop.

The gravitational process is based on the use of the force of gravity, when minerals are separated from waste rock due to the difference of their density and particle size. This principle is illustrated by the separation of sand from sawdust when it is thrown into the water: sawdust floats while the sand sinks in water.

The final product resembles mud but it’s probably the most expensive mud in the world.

This is the shop of hydrometallurgy, where gold is also extracted from the ore by means of aqueous solutions with certain chemicals.

This Dore bar is what they get in the very end. It contains 80 % of gold and 20 % of silver. Such bars are sent to the refining factory where they turn into ready bars of precious gold.

via voxpopuli

Sem comentários:

Enviar um comentário